CONTROL ENGINEERING

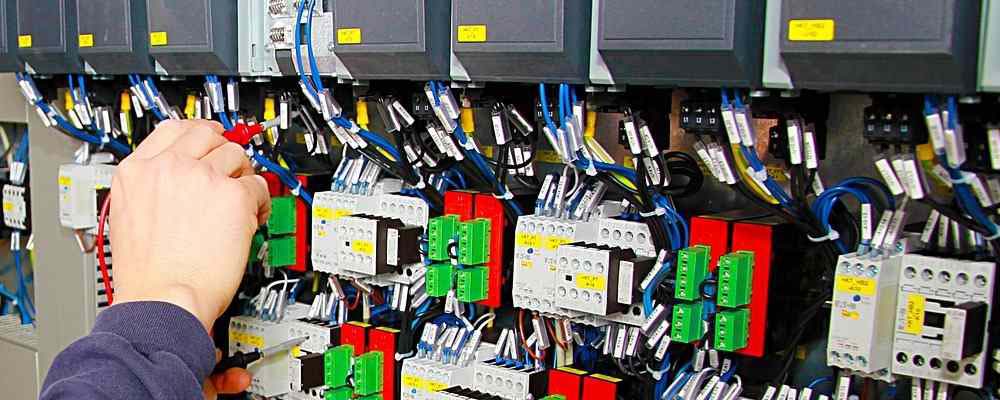

Spraw Systems' provides control engineering services for a wide variety of process and manufacturing industries, and can address even the most challenging custom control system design requirements. Our teams comprise of individuals equipped with vast automation engineering and programming expertise, who also possess the in-depth process knowledge that is necessary to address our customers' unique and distinct needs.

Design Services

As part of Spraw Systems' control engineering services offering, we provide vendor-neutral services in the industrial automation space. Our knowledge of automation across the business and plant layers makes our approach more integrated and efficient than if the integration is done in isolation. Some of the typical features of design services are:

Turnkey Project Services

We offer a full portfolio of turnkey services from consulting, to design and engineering, to safety studies and energy management audits, and to power quality and reliability audits. Whether it's upgrading an existing production facility or building a brand new facility, our project services are:

Consulting Services

In addition to turnkey project services, we also undertake system wide studies, offering valuable inputs to the customers:

Maintenance Support Services

Our field technicians and customer support engineers can start up and commission equipment, perform planned maintenance, monitor performance and diagnose problems, and respond to emergencies on a 24x365 basis. Where ever desired by the customers, remote monitoring of system parameters could be provided using customised hardware and networking solutions. Our comprehensive maintenance services help our customers to:

Spraw System Advantage

Domain expertise:We focus on all aspects of process and manufacturing operations, leveraging technology to solve complex production problems.

Customisation: Out of the box solutions and services geared to your specific needs

Full services:We provide end to end support to our customers ranging from conceptualization, design and development and operational support.

Proven technology: Our experience with technology and vast pool of industry experts with us helps us craft a well defined road map for operational excellence for our customers.

Added Benefits

Control Applications

Benefits

- Related Processes